- Home

- Product Center

- Hydrogen reduction furnace

- Rotary

- Liquid-gas CVD all-in-one machine

Product Center

Phone: 400-000-3746

- Tube furnace

- Muffle furnace

- CVD system

- Hydrogen reduction furnace

- Rotary furnace

- Ultra-high temperature sintering furnace

- Induction heating furnace

- Molten salt furnace

- Lift,Shaft,Crucible Furnace

- Hardening furnace

- Specific Process Series

- Drying Box Series

- Ball-milling mixer

- Tablet press series

- Vacuum system

- Gas supply system

- Industrial furnace

- Related Accessories

- Crystals and targets

Contact Us

Sale Service: 0371-6320 2801

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China

Liquid-gas CVD all-in-one machine

Release time: 2024-07-10 03:41:12 Number of views: 126

Equipment introduction:

Chemical vapor deposition (CVD) refers to the reaction of chemical gases or vapors on the surface of the substrate to synthesize coatings or nanomaterials. It is the most widely used technology in the semiconductor industry to deposit thin film materials, including a wide range of insulation materials, as well as most metal materials and metal alloy materials. To this end, we developed a complete set of CVD coating system, which is suitable for material laboratories, scientific research institutes, environmental science and other fields;

This equipment is customized based on customer requirements in the field of new energy. The reaction gases include inflammable and explosive, poisonous and harmful gases, and liquid gasification through the gas phase generator. Multi-channel mass flowmeter precisely controls intake volume. High precision pressure sensor, solenoid valve, gas detector, alarm and exhaust treatment tank, to ensure the safe, efficient and harmless discharge

Equipment introduction:

Chemical vapor deposition (CVD) refers to the reaction of chemical gases or vapors on the surface of the substrate to synthesize coatings or nanomaterials. It is the most widely used technology in the semiconductor industry to deposit thin film materials, including a wide range of insulation materials, as well as most metal materials and metal alloy materials. To this end, we developed a complete set of CVD coating system, which is suitable for material laboratories, scientific research institutes, environmental science and other fields;

This equipment is customized based on customer requirements in the field of new energy. The reaction gases include inflammable and explosive, poisonous and harmful gases, and liquid gasification through the gas phase generator. Multi-channel mass flowmeter precisely controls intake volume. High precision pressure sensor, solenoid valve, gas detector, alarm and exhaust treatment tank, to ensure the safe, efficient and harmless discharge

Configuration:

| 1. Ensure anaerobic working environment through high-precision oxygen analyzer;

| ||||||||

Model | NBD-RT1200-120T2D5ZYW-N | ||||||||

Three-phase 380V 50HZ | |||||||||

Temp Accuracy | ±1℃ | ||||||||

| rated power | 8KW | ||||||||

| Thermocouple type | Type K thermocouple 250mm | ||||||||

| Tmax | 1100℃ | ||||||||

| Size of heating zone | φ150*430mm | ||||||||

| Tube material | High purity quartz | ||||||||

| Furnace tube volume | 5L | ||||||||

| Effective volume of sample | 500ml | ||||||||

| angle of inclination | -20 degrees (discharge) ~3 degrees (feed) | ||||||||

| Tube speed | 0.1~12.6 r/min | ||||||||

| Furnace body size | Length 1550× depth 830× height 1360mm (including acetylene alarm 2160mm) | ||||||||

Recommended heating rate | 10℃/min | ||||||||

Net weight | Approx.260KG | ||||||||

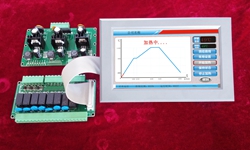

| Control system |

| 1, sintering process curve setting: dynamic display setting curve, equipment sintering can prestore multiple process curves, each process curve can be set freely; | |||||||

* Support non – calibration, more models, welcome to call 400-000-3746 | |||||||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

推荐产品

Spiral heater

Safe automatic frit furnace

Battery Tester 5V100mA Quad Range (BT-2018R)

Liquid Vapor Phase Generator (Type II)