- Home

- Product Center

- Specific Process Series

- Rapid annealing

- Insulation sheet die

Product Center

Phone: 400-000-3746

- Tube furnace

- Muffle furnace

- CVD system

- Hydrogen reduction furnace

- Rotary furnace

- Ultra-high temperature sintering furnace

- Induction heating furnace

- Molten salt furnace

- Lift,Shaft,Crucible Furnace

- Hardening furnace

- Specific Process Series

- Drying Box Series

- Ball-milling mixer

- Tablet press series

- Vacuum system

- Gas supply system

- Industrial furnace

- Related Accessories

- Crystals and targets

Contact Us

Sale Service: 0371-6320 2801

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China

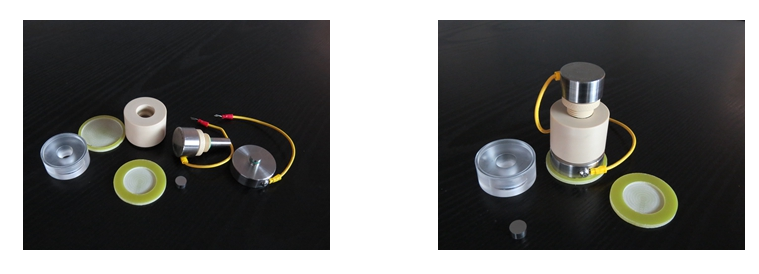

Insulation sheet die

Release time: 2024-07-10 03:41:12 Number of views: 126

The combination of insulation die and powder tablet machine is an essential tool for infrared, fluorescence, calcium and iron analysis instruments, and an indispensable tool for the analysis and research of new powder materials in various fields.

In addition to the standard pressure mould, there are vacuumable cylindrical mould, large cylindrical mould with spring, open flap mould (round, rectangular, shaped), hot pressing mould, insulation mould, etc.

The insulation pressure mold is made of PEEK material, which has the characteristics of high hardness, good toughness, excellent finish, accurate precision and long life.

The combination of insulation die and powder tablet machine is an essential tool for infrared, fluorescence, calcium and iron analysis instruments, and an indispensable tool for the analysis and research of new powder materials in various fields.

In addition to the standard pressure mould, there are vacuumable cylindrical mould, large cylindrical mould with spring, open flap mould (round, rectangular, shaped), hot pressing mould, insulation mould, etc.

The insulation pressure mold is made of PEEK material, which has the characteristics of high hardness, good toughness, excellent finish, accurate precision and long life.

Instructions for use:

The insulating mold is used for the production of on-line solid-state battery, which is generally used in the glove box with the transfer fixture and the powder tablet press;

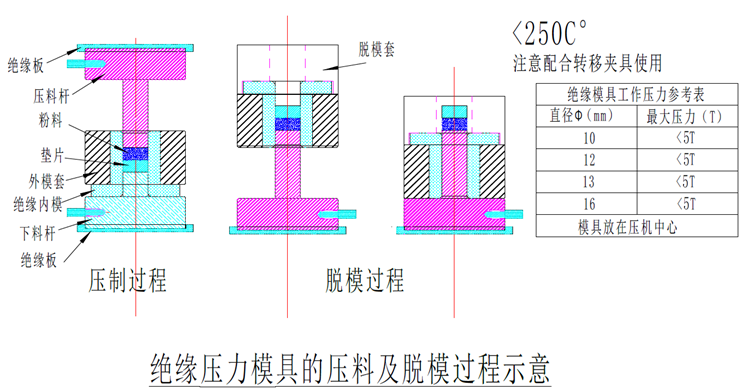

Pressing process: First place the mold cover on the bottom of the mold in the glove box, and put a gasket (large molds do not have gaskets). Then the positive and negative battery materials are evenly filled in, and then the powder in the hole is rolled flat with the press rod to compact the press column, and then the mold is placed in the center of the transfer fixture table with the die bottom down. And tighten the screws. After that, the transfer fixture is placed in the center of the tablet press table, and then the screw screw of the tablet press is rotated downward until it is against the press rod. After adding the required pressure, tighten the top screw of the transfer fixture again. (Apply a small amount of vacuum grease or petroleum jelly to the gap between the press rod and the inner mold sleeve, or take out the glove box test).

Stripping process: the transfer fixture is removed during mold withdrawal, the whole mold is inverted, the mold bottom is removed, the mold sleeve is put on, and the screw of the press machine is unscrew or pressed to return the sample.

推荐产品

Light duty melting furnace

Production vacuum atmosphere pendulum rotary sintering furnace 1200℃

Glove box plus high temperature furnace, etc

Ion sputtering coating instrument